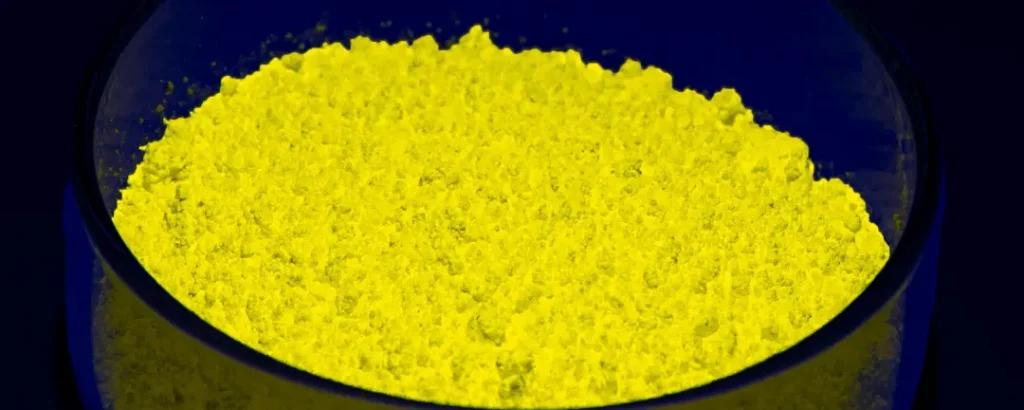

Safety is a top priority when it comes to designing and manufacturing children’s equipment. From playground installations and sports gear to classroom toys, every component must be visible, durable, and safe for children to use. Some aspects might seem obvious, like ensuring there are no sharp edges. But did you know that fluorescent pigments play a key role in children’s equipment safety and durability?

Fluorescent pigments offer unique benefits, contributing to compliance and improving both functional and aesthetic appeal. In this article, we’ll explore how they’re applied and why Angstrom Technologies Inc. is a trusted leader in fluorescent pigment solutions.

What Role Do Fluorescent Pigments Play in Children’s Equipment?

The color of children’s play equipment might not seem important. But applying fluorescent pigments goes beyond subjective color choices. Here’s how they help keep children’s equipment safe while encouraging fun.

High Visibility

Fluorescent pigments are engineered to absorb UV light and re-emit it as bright, visible color within the daylight spectrum. This makes safety features on children’s equipment–like handles, steps, and warning edges–more visible both indoors and outdoors.

Fun Factor

Beyond function, vibrant fluorescent colors foster engagement and enjoyment. This makes toys and equipment more appealing to the community. This is ideal for schools, municipalities, and park boards who want to create bright, welcoming spaces for children to play safely.

Authentication and Brand Trust

Distinct fluorescent hues can be used for brand recognition, ensuring that authentic products are easily identifiable in retail settings or shared environments. Fluorescent pigments also provide anti-counterfeiting security benefits. Proprietary covert fluorescent markings help verify genuine equipment, protecting against unsafe knock-offs.

Durability and Strength That Go Beyond the Surface

Creating children’s equipment that can withstand heavy use—and still meet safety and aesthetic standards—requires more than strong materials. The pigments used in coatings, plastics, and decorations must also be engineered for long-term durability.

Long-Lasting Performance in Real-World Conditions

Children’s equipment is exposed to a range of challenging conditions, including UV rays from prolonged outdoor use, repeated handling by children, friction from play, and regular cleaning with harsh disinfectants. Inferior pigments can fade, discolor, or degrade under these conditions, compromising both the product’s appearance and safety compliance.

For over 40 years, Angstrom Technologies Inc. has specialized in high-quality fluorescent pigments. Our products are specifically formulated to:

- Resist photodegradation under prolonged UV exposure, retaining their brightness and vibrancy.

- Withstand mechanical abrasion from frequent contact and impact without flaking or fading.

- Remain chemically stable during routine cleaning with soaps, sanitizers, or disinfecting wipes.

- Maintain color integrity in various substrates, including plastics, coatings, silicone, and rubber.

This ensures that safety features—such as high-visibility edges or grip zones—continue performing as intended, without loss of effectiveness over time.

Reliable, Low-Maintenance Operation

Fluorescent pigments that hold up under heavy wear offer more than just safety—they also reduce the total cost of ownership. For schools, playground operators, and childcare centers, that means:

- Consistent compliance, even after extended use.

- Fewer repairs or replacements due to cosmetic damage or fading.

- Products that continue to look great, reassuring parents and reinforcing brand quality.

From design to day-to-day use, pigments from Angstrom Technologies Inc. are built to meet the real-world maintenance expectations of both manufacturers and end users.

Compliance Standards for Fluorescent Pigments in Children’s Equipment

Stringent regulations govern the manufacturing and use of children’s equipment worldwide. Fluorescent pigments used in these products must meet strict safety and performance benchmarks.

| Standard | Region / Body | Scope and Applicability |

|---|---|---|

| ASTM F963 | United States | Encompasses toy safety, including the chemical composition of pigments and surface coatings. |

| EN71-3 | European Union | Restricts heavy metals and harmful substances in accessible materials of toys. |

| ISO 8124 | International | Addresses the mechanical and chemical safety of toys, including coloration. |

| CPSIA | United States | Limits lead and phthalates in children’s products, impacting pigment selection. |

Equipment manufacturers must guarantee that the use of fluorescent pigments in children’s equipment complies with all applicable standards regarding toxicity, migration of elements, and performance under normal use.

Overview of the Pigment Selection Process

At Angstrom Technologies Inc., we’ll work with you to explore the right custom pigment solutions for your needs. Here are some things to consider to keep your children’s equipment safe and in top condition.

Toxicological Evaluation and Child-Safe Certification

- Ingredient Safety: Fluorescent pigments for children’s use are rigorously evaluated for heavy metals, PAHs (polycyclic aromatic hydrocarbons), allergenic dyes, and other potential hazards.

- Migration Testing: Certified pigments must not leach harmful substances even when equipment is mouthed or exposed to sweat or humidity.

- Documentation: Reputable pigment suppliers provide detailed safety data sheets, testing protocols, and certification against ASTM, EN71, or relevant local standards.

What To Look For in Pigment Choice

- Provenance: Source pigment products from suppliers with a strong track record in regulatory compliance.

- Performance Data: Assess fade resistance, color stability, and compatibility with plastics, coatings, and other materials.

- Customization: Select pigments capable of matching specific shades or effects while still maintaining safety certifications.

Angstrom Technologies Inc.’s Commitment to Innovation

Angstrom Technologies Inc. invests heavily in research, testing, and quality control to deliver industry-leading pigment solutions. Our team attends global events and stays ahead of changing regulations and emerging scientific knowledge to develop products that combine exceptional visibility with uncompromising safety standards.

- We conduct ongoing research to ensure new pigment formulations exceed compliance thresholds and anticipate shifts in global regulations and consumer expectations.

- Our robust validation processes ensure every pigment batch is tested for colorfastness, photostability, and non-toxicity across a range of polymers and surface applications.

Product Customization for OEM Partners

Recognizing that every brand and application is unique, Angstrom delivers fully customized pigment solutions tailored to specific substrate materials, colors, and marketing needs. Whether you require a custom fluorescent yellow for playground slides or an invisible pigment for authentication, their team works closely with design and compliance managers to ensure maximum effectiveness and safety.

Partner With Angstrom Technologies Inc.

Angstrom Technologies Inc. offers pigment solutions that make children’s equipment safer, more visible, and fully compliant. Reach out today to find the right innovative pigments to set your products apart–while giving parents, regulators, and your brand peace of mind.